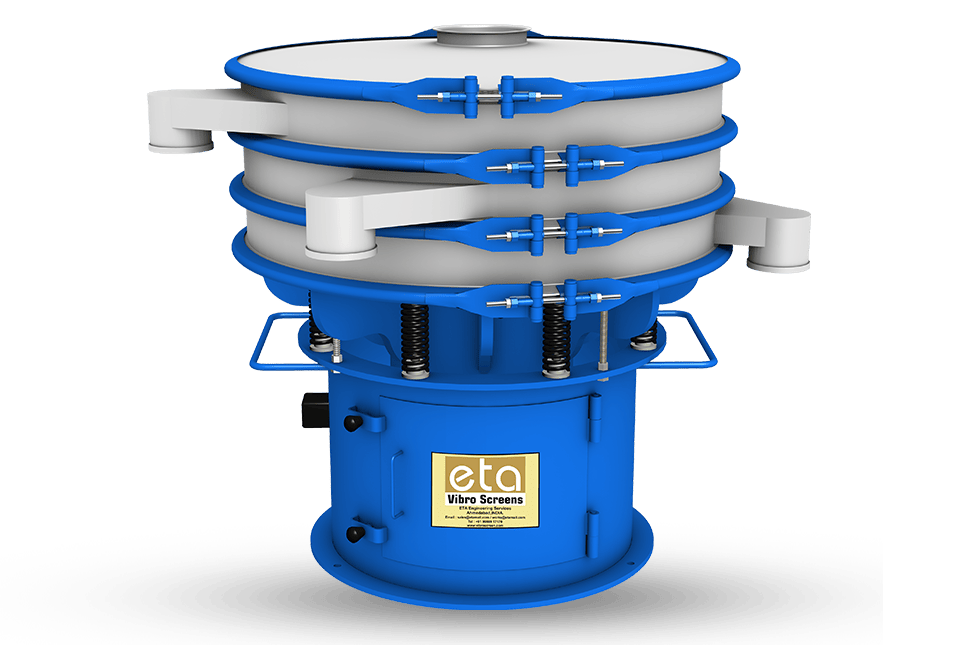

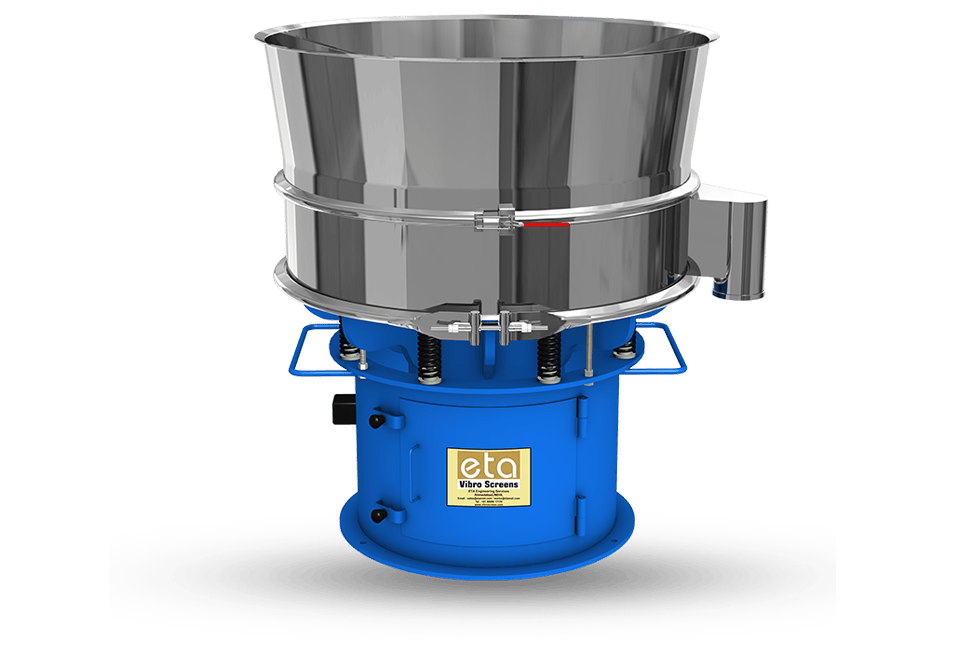

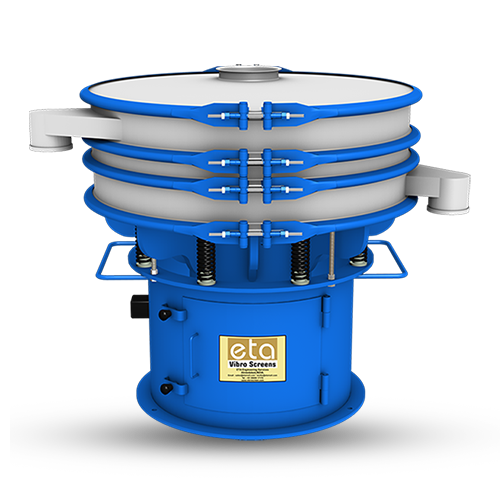

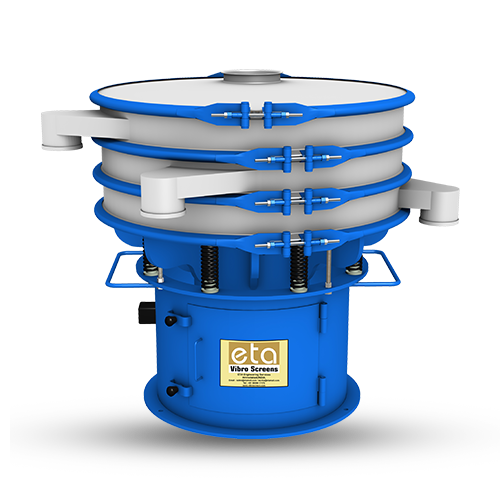

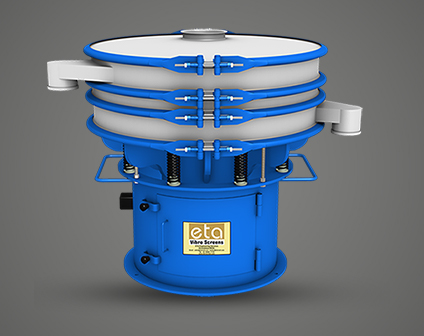

Welcome to ETA Engineering Services

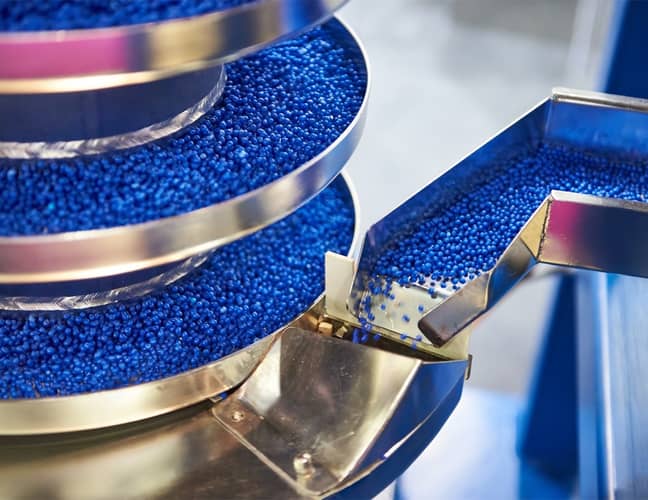

Welcome to Eta Engineering Services, the dedicated and committed specialists of vibratory equipment. Since 1995 we have been focusing exclusively on design, development and manufacturing of Gyratory Screens. Our company is promoted by technocrats in the field of mechanical engineering and process industry having in-depth understanding of various processes, operations, materials, equipments and quality systems...